Unitronics enables you to implement Motion via EtherCAT and CANopen.

EtherCAT communications are via the Unitronics EtherCAT master module. In addition to acting as the gateway for all EtherCAT communication, the master module acts as a motion controller, building the motion profile.

CANopen communications are either via a port located directly on the CPU, or via a CANbus Add-on communication port.

Unitronics offers a full line of servo drives and motors for your motion application needs. UniLogic greatly simplifies servo applications by enabling you to:

Drag & drop drives and motors into your project: UniLogic automatically defines the correct configuration and automatically sets up communications for you

Add up to 8 discrete/cyclical Axes, drag & drop actuators; UniLogic automatically converts units

Benefit from automatic calculations: UniLogic analyzes the mechanical properties of your selections and recommends safe values

Use the Ready-made Motion application to execute movements, such as Point-to-Point, Jog, and Homing--you can open this application and edit as needed to adapt it to your motion requirements

Program Motion Control via drag & drop, using industry standard motion Function Blocks (PLCopen)

Tune your system using a single parameter

Diagnostics: View servo run-time performance via UniLogic’s built-in powerful, high-speed scope

The Motion Control functions currently supported are:

|

Controls the power flow to the Axis (On or Off). |

|

|

Commands the axis to perform the «search home» sequence set in Axis> Homing. |

|

|

Decelerates the axis according to the emergency deceleration defined in the axis parameters. |

|

|

Decelerates the axis according to the rate of deceleration you define in MC Halt. |

|

|

Commands a controlled motion to a specified absolute position |

|

|

Commands a controlled motion of a specified distance relative to the set position at the time of the execution |

|

|

Commands a controlled motion of a specified, relative distance additional to the most recent commanded axis position. |

|

|

Commands a never-ending controlled motion at a specified velocity. |

|

|

Continuously exerts a torque or force of the specified magnitude. |

|

|

Enables you to set Torque and apply it according to the physical values you define in the Axis Configuration, regardless of the motor specification. |

|

|

Enables you to set Force and apply it according to the physical values you define in the Axis Configuration, regardless of the motor specification (linear actuators only. |

|

|

Shifts the coordinate system of an axis by manipulating both set-point position and actual position. |

|

|

Transitions the axis state ‘ErrorStop’ to ‘Standstill’ or ‘Disabled’ by resetting all internal axis-related errors. |

|

|

Commands Jog forward or backward. Jog is a Unitronics' function, not part of the PLCopen standard. |

|

|

This FB returns the value of a specific parameter. |

|

|

This FB writes a value to a specific parameter. |

Multi-Axes Functions (EtherCAT)

|

When the axes are configured to Mode: Cyclic, the EtherCAT master module acts as a motion controller and generates the motion profile at each cycle. With Multi-Axis Function Blocks a synchronized relationship exists between two or more axes. |

|

|

Commands a ratio between the VELOCITY of the slave and master axis. |

|

|

Disengages the Slave axis from the Master axis |

|

|

Commands a gear ratio between the position of the slave and master axes from the synchronization |

|

|

Combines the motion of 2 axes into a third axis with selectable combination method |

|

|

Selects the CAM tables by setting the connections to the relevant tables |

|

|

Engages the Cam |

|

|

Immediately disengages the Slave axis from the Master axis |

|

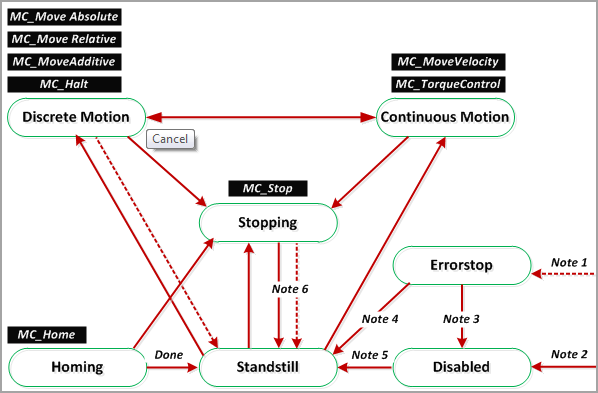

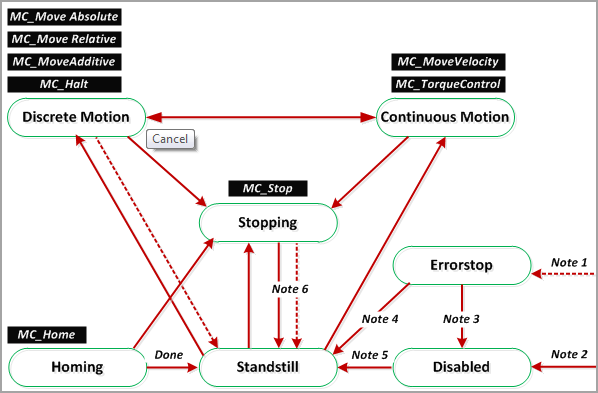

The next diagram has been adapted from the PLCopen State diagram to show the states and motion actions currently supported by UniLogic.

Note 1: From any state. An error in the axis occurred.

Note 2: From any state. MC_Power.Enable = FALSE and there is no error in the axis.

Note 3: MC_Reset AND MC_Power.Status = FALSE

Note 4: MC_Reset AND MC_Power.Status = TRUE AND MC_Power.Enable = TRUE

Note 5: MC_Power.Enable = TRUE AND MC_Power.Status = TRUE

Note 6: MC_Stop.Done = TRUE AND MC_Stop.Execute = FALSE

Configurations contain drive-related parameters, which you can edit to suit your application.

During the Configuration process, as you add drives, motors, and axes, UniLogic automatically creates operand structs that you can use in your motion application.