|

|

|

|

|

Enable Communication

|

BIT

|

Turn this ON to allow communications between UniStream and the Servo drive.

This bit is On by default.

This bit must be on in order for the drive to function; when it is OFF the PLC cannot communicate with the drive.

|

|

Current Configuration Name

|

STRING-ASCII

|

The name assigned to the Servo drive

|

|

Communication Statistics

|

UINT32

|

[Action successes counter]

|

|

|

UINT32

|

[Action failures counter]

|

|

|

UINT32

|

[Action timeout counter]

|

|

|

UINT32

|

[Message sent]

|

|

|

UINT32

|

[Messages received successfully]

|

|

|

UINT32

|

[Message received erroneously]

|

|

|

UINT32

|

[Failed SDO Index]

|

|

|

UINT32

|

[Failed SDO SubIndex]

|

|

|

UINT32

|

|

|

Function selection switches

|

UINT16

|

[Servo General Parameters1]

|

|

|

UINT16

|

[Servo General Parameters2]

|

|

|

UINT16

|

[Servo General Parameters3]

|

|

|

UINT16

|

[Servo General Parameters4]

|

|

|

UINT16

|

[Servo General Parameters5]

|

|

|

UINT16

|

[Servo General Parameters6]

|

|

|

UINT16

|

[Servo General Parameters7]

|

|

|

UINT16

|

[Servo General Parameters8]

|

|

|

UINT16

|

[Electronic Gear]

|

|

|

UINT16

|

|

|

Parameters of servo gain

|

UINT16

|

[Autotuning Settings]

|

|

|

UINT16

|

[Machine Rigidity Setting]

|

|

|

UINT16

|

[Speed Loop Gain]

|

|

|

UINT16

|

[Speed Loop Integral Time Constant]

|

|

|

UINT16

|

[Position Loop Gain]

|

|

|

UINT16

|

[Torque Reference Filter Time Constant]

|

|

|

UINT16

|

[Servo gain]

|

|

|

UINT16

|

[_2nd Speed Loop Gain]

|

|

|

UINT16

|

[_2nd Speed Loop Integral Time]

|

|

|

UINT16

|

[_2nd Position Loop Gain]

|

|

|

UINT16

|

[_2nd Torque Reference Filter Time Constant]

|

|

|

UINT16

|

[Speed Bias]

|

|

|

UINT16

|

[Speed Feedforward]

|

|

|

UINT16

|

[Speed Feedforward Filter Time Constant]

|

|

|

UINT16

|

[Torque Feedforward]

|

|

|

UINT16

|

[Torque Feedforward Filter Time Constant]

|

|

|

UINT16

|

[P/PI Switching Condition]

|

|

|

UINT16

|

[Torque Switching Threshold]

|

|

|

UINT16

|

[Offset Counter Switching Threshold]

|

|

|

UINT16

|

[Setting Acceleration Speed Switching Threshold]

|

|

|

UINT16

|

[Setting Speed Switching Threshold]

|

|

|

UINT16

|

[Gain Switching Condition]

|

|

|

UINT16

|

[Gain Switching Waiting Time]

|

|

|

UINT16

|

[Switch Threshold Level]

|

|

|

UINT16

|

[Actual Speed Threshold]

|

|

|

UINT16

|

[Position Loop Gain Switching Time]

|

|

|

UINT16

|

[Hysteresis Switching]

|

|

|

UINT16

|

[Low Speed Detection Filter]

|

|

|

UINT16

|

[Speed Gain Acceleration Relationship During Online Autotuning]

|

|

|

UINT16

|

[Low Speed Correction Coefficient]

|

|

|

UINT16

|

[Friction Load]

|

|

|

UINT16

|

[Speed Lag Ring of Friction Compensation]

|

|

|

UINT16

|

[Viscous Friction Load]

|

|

|

UINT16

|

[Notch Filters 1 Trap Width]

|

|

|

UINT16

|

[Notch Filters 2 Trap Width]

|

|

|

UINT16

|

|

|

Position control related parameters

|

UINT16

|

[PG Divider]

|

|

|

UINT16

|

[_16 Bit 1st Electronic Gear Numerator]

|

|

|

UINT16

|

[_16 Bit Electronic Gear Denominator]

|

|

|

UINT16

|

[_16 Bit 2nd Electronic Gear Numerator]

|

|

|

UINT16

|

[Position Reference Filter Time Constant]

|

|

|

UINT16

|

[Position Reference Filter Mode Selection]

|

|

|

UINT16

|

|

|

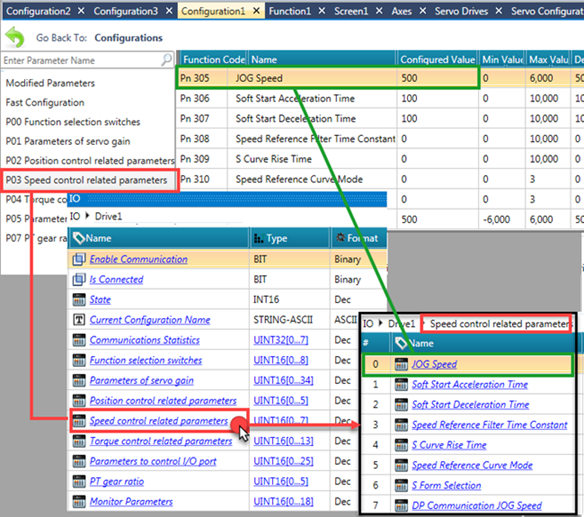

Speed control related parameters

|

UINT16

|

[JOG Speed]

|

|

|

UINT16

|

[Soft Start Acceleration Time]

|

|

|

UINT16

|

[Soft Start Deceleration Time]

|

|

|

UINT16

|

[Speed Reference Filter Time Constant]

|

|

|

UINT16

|

[S Curve Rise Time]

|

|

|

UINT16

|

[Speed Reference Curve Mode]

|

|

|

UINT16

|

[S Form Selection]

|

|

|

UINT16

|

[DP Communication JOG Speed]

|

|

|

UINT16

|

|

|

Torque control related parameters

|

UINT16

|

[Forward Internal Torque Limit]

|

|

|

UINT16

|

[Reverse Internal Torque Limit]

|

|

|

UINT16

|

[Forward External Torque Limit]

|

|

|

UINT16

|

[Reverse External Torque Limit]

|

|

|

UINT16

|

[Reversal Connections Braking Torque Limit]

|

|

|

UINT16

|

[Speed Limit During Torque Control]

|

|

|

UINT16

|

[_1st Notch Filter Frequency]

|

|

|

UINT16

|

[_1st Notch Filter Depth]

|

|

|

UINT16

|

[_2nd Notch Filter Frequency]

|

|

|

UINT16

|

[_2nd Notch Filter Depth]

|

|

|

UINT16

|

[Frequency of Low Frequency Jitter]

|

|

|

UINT16

|

[Damp of Low Frequency Jitter]

|

|

|

UINT16

|

[Torque Control Delay Time]

|

|

|

UINT16

|

[Torque Control Speed Lag]

|

|

|

UINT16

|

|

|

Parameters to control I/O port

|

UINT16

|

[Positioning Error]

|

|

|

UINT16

|

[Coincidence Difference]

|

|

|

UINT16

|

[Zero Clamp Speed]

|

|

|

UINT16

|

[Rotation Detection Speed]

|

|

|

UINT16

|

[Position Error Pulse Counter Overflow Alarm Selection]

|

|

|

UINT16

|

[Servo On Waiting Time]

|

|

|

UINT16

|

[Basic Waiting Flow]

|

|

|

UINT16

|

[Brake Waiting Speed]

|

|

|

UINT16

|

[Brake Waiting Time]

|

|

|

UINT16

|

[Inputs Selection Group1]

|

|

|

UINT16

|

[Inputs Selection Group2]

|

|

|

UINT16

|

[Outputs Selection]

|

|

|

UINT16

|

[Inputs Enable Group1]

|

|

|

UINT16

|

[Inputs Enable Group2]

|

|

|

UINT16

|

[Input Port Filter]

|

|

|

UINT16

|

[Alarm Port Filter]

|

|

|

UINT16

|

[Inputs Inverse Group1]

|

|

|

UINT16

|

[Inputs Inverse Group2]

|

|

|

UINT16

|

[Dynamic Brake Time]

|

|

|

UINT16

|

[Serial Encoder Error Time]

|

|

|

UINT16

|

[Position Complete Time]

|

|

|

UINT16

|

[Regenerative Resistor]

|

|

|

UINT16

|

[Overload Alarm Threshold]

|

|

|

UINT16

|

[Outputs Inverse]

|

|

|

UINT16

|

[Torque Detection Signal Output Threshold Value]

|

|

|

UINT16

|

[Torque Detection Output Signal Time]

|

|

|

UINT16

|

|

|

PT gear ratio

|

UINT16

|

[_32 Bit 1st Electronic Gear Numerator (H)]

|

|

|

UINT16

|

[_32 Bit 1st Electronic Gear Numerator (L)]

|

|

|

UINT16

|

[_32 Bit Electronic Gear Denominator (H)]

|

|

|

UINT16

|

[_32 Bit Electronic Gear Denominator (L)]

|

|

|

UINT16

|

[_32 Bit 2nd Electronic Gear Numerator (H)]

|

|

|

UINT16

|

[_32 Bit 2nd Electronic Gear Numerator (L)]

|

|

|

UINT16

|

|

|

Monitor Parameters

|

UINT16

|

[Actual servomotor speed]

|

|

|

UINT16

|

[Input speed reference]

|

|

|

UINT16

|

[Input torque reference (with respect to rated torque)]

|

|

|

UINT16

|

[Internal torque reference (with respect to rated torque)]

|

|

|

UINT16

|

[Number of encoder rotation angle pulses]

|

|

|

UINT16

|

[Input signal monitor]

|

|

|

UINT16

|

[Encoder signal monitor]

|

|

|

UINT16

|

[Output signal monitor]

|

|

|

UINT16

|

[Frequency given by pulse]

|

|

|

UINT16

|

[Number of servomotor rotation pulses]

|

|

|

UINT16

|

[Pulse rate of servomotor rotated]

|

|

|

UINT16

|

[Error pulse counter lower 16 digit]

|

|

|

UINT16

|

[Error pulse counter higher 16 digit]

|

|

|

UINT16

|

[Number of pulses given]

|

|

|

UINT16

|

[Number of pulses given (x10000)]

|

|

|

UINT16

|

[Load inertia percentage]

|

|

|

UINT16

|

[Servomotor overload ratio]

|

|

|

UINT16

|

[Encoder EEPROM saves motor and encoder types and correlation information]

|

|

|

UINT16

|

[Nikon Encode internal Temperature]

|