Information Mode is a utility that is embedded in the operating system of the controller. Via Information Mode, you can view data on the LCD screen, use the controller’s keyboard to directly edit data, and perform certain actions such as resetting the controller. You can enter Information Mode at any time without regard to what is currently displayed on the LCD screen.

The categories of available information depend on the controller model. The table below shows the basic categories of information.

|

|

|

|

|

Data Types

|

Memory Bits

|

|

|

|

System Bits

|

|

|

Memory Integers

System Integers

Memory Longs

System Longs

Memory Double Words

System Double Words

|

|

|

Inputs

|

|

|

Outputs

|

|

|

Timers

|

|

|

|

TCP/IP (Standard Vision, Visible when Ethernet card is installed)

|

Enables you to view and edit IP address and socket settings.

|

|

System

|

Model & O/S Ver

|

|

|

|

Working Mode

|

-

Check whether the controller is in Run or Stop mode.

-

Reset the controller. This restarts your program; restoring power-up values to all data types except for those protected by the battery backup. The battery protects Real Time Clock (RTC), all operand, and Data Table values.

-

Initialize the controller. This restarts your program and initializes all values, restoring 0 values to all data types.

|

|

|

Time & Date

|

|

|

|

Unit ID

|

The Unit ID number identifies a networked controller. You can:

|

|

|

Serial Port 1

Serial Port 2

|

|

|

|

Ethernet (Enhanced Vision, if an Ethernet card is installed)

|

Enables you to view and edit IP address, Socket settings, and other TCP/IP settings.

|

|

|

Monitor Communications

(Enhanced only)

|

This is a built-in communications 'sniffer'

-

Touch screen models: select Serial or Ethernet, then press Monitor. Note the button that allows you to toggle between Hex and ASCII

-

Non-touch screen models: Select Communication, then select Serial or Ethernet> COM Buffer. Use F2 to toggle between Hex and ASCII. In addition, press Enter, and then the Down key to toggle between. Tx and Rx.

|

|

|

CANbus

|

|

|

|

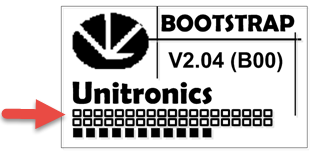

Erase ALL PLC Data (V230 / V280 ONLY)

|

This completely erases all of the PLC's data,the OS, application, operand data, and Data Tables.

Note that after you select Erase All PLC Data, and confirm that you want to continue:

-

The PLC enters bootstrap mode.

-

A row of black boxes will appear at the bottom of the screen.

At any point after the first box appears, press the Enter key.

-

A row of white boxes will appear above the black boxes.

-

Wait until an entire row has been completed, and a second one has begun to appear.

-

Establish communications with the PLC, and download an OS.

|

|

|

Touchscreen (Touchscreen models only)

|

Enables you to calibrate the touchscreen, if it is not responding accurately to screen taps.

|

|

(Enhanced Division)

|

Removable memory storage

|

Enables you to upload and download VisiLogic applications, OS firmware, and Data Table data from/to an SD card.

You can use these features to a PLC application.

|

|

Function Block

|

Reserved for future use

|

|

|

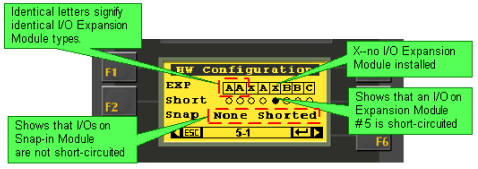

Hardware Configuration

|

|

-

Check if I/O Expansion Modules are installed. Note that I/O Expansion Modules are represented by letters. Identical module types are represented by identical letters as shown below.

-

Shows if an I/O module is short-circuited.

|