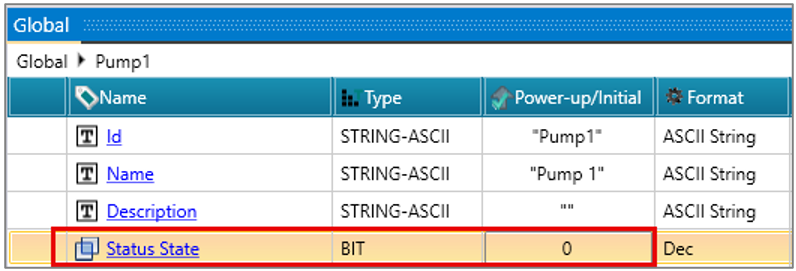

|

Name

|

Data Type

|

Definition

|

|

ID

|

STRING-ASCII

|

This is a unique ID name

|

|

Name

|

STRING-ASCII

|

This is a name that you assign for your own reference.

|

|

Description

|

STRING-ASCII

|

A brief textual explanation of the object or resource.

|

|

Status State

|

BIT

|

Indicates the current status or state of the object

|

|

Status Health

|

UINT8

|

Represents the health status of the object or resource

|

|

0= Critical

|

A critical condition requires immediate attention

|

|

1= OK

|

Normal

|

|

2= Warning

|

A condition requires attention

|

|

Enabled

|

BIT

|

Indicates whether the sensor is enabled and provides a reading

|

|

Reading

|

REAL

|

The sensor value

|

|

Reading Units

|

STRING-ASCII

|

The units of the reading, thresholds, and other reading-related properties in UCUM c/s format

|

|

Reading Type

|

UINT8

|

The type of the sensor

|

|

0= AbsoluteHumidity

|

Indicates the absolute (volumetric) humidity, measured in grams per cubic meter (g/m³)(v1.5+)

|

|

1= AirFlow

|

Indicates the gas volume per unit of time flowing through a junction, measured in cubic feet per minute (ft³/min)(deprecated v1.7)

|

|

2= AirFlowCMM

|

Indicates the gas volume per unit of time flowing through a junction, measured in cubic meters per minute (m³/min)(v1.7+)

|

|

3= Altitude

|

Indicates the elevation above sea level, measured in meters (m)

|

|

4= Barometric

|

Indicates barometric pressure, measured in millimeters of mercury (mmHg)

|

|

5= ChargeAh

|

Indicates the total electric charge (integral of current over time), measured in ampere-hours (A·h). Reflects consumption since the last sensor reset (v1.4+)

|

|

6= Current

|

Indicates RMS current measured over complete line cycles, expressed in amperes (A)

|

|

7= EnergyJoules

|

Indicates energy (integral of real power over time), measured in joules (J). Used for device-level energy consumption; for large-scale measurements, use EnergykWh (v1.23+)

|

|

8= EnergykWh

|

ndicates energy (integral of real power over time), measured in kilowatt-hours (kW·h). Used for large-scale energy consumption; for device-level measurements, use EnergyJoules or EnergyWh

|

|

9= EnergyWh

|

Indicates energy (integral of real power over time), measured in watt-hours (W·h). Used for device-level energy consumption; for large-scale measurements, use EnergykWh (v1.4+)

|

|

10= Frequency

|

Indicates frequency, measured in hertz (Hz)

|

|

11= Heat

|

Indicates heat measurement, expressed in kilowatts (kW) (v1.7+)

|

|

12= Humidity

|

Indicates relative humidity, expressed as a percentage (%)

|

|

13= LiquidFlow

|

Indicates liquid flow rate, measured in liters per second (L/s) (deprecated v1.7)

|

|

14= LiquidFlowLPM

|

Indicates liquid flow rate, measured in liters per minute (L/min) (v1.7+)

|

|

15= LiquidLevel

|

Indicates fluid height, measured in centimeters (cm) relative to a reference datum

|

|

16= Percent

|

Indicates a percentage value (%). The reading typically ranges from 0–100 but may exceed 100 for rate-of-change or similar values (v1.1+)

|

|

17= Power

|

Indicates average power (product of instantaneous voltage and current), measured in watts (W)

|

|

18= Pressure

|

Indicates applied force per unit area, measured in pascals (Pa) (deprecated v1.7)

|

|

19= PressurekPa

|

Indicates pressure relative to atmospheric pressure, measured in kilopascals (kPa) (v1.5+)

|

|

20= PressurePa

|

Indicates pressure relative to atmospheric pressure, measured in pascals (Pa) (v1.7+)

|

|

21= Rotational

|

Indicates rotational speed, measured in revolutions per minute ({rev}/min). RPM is a deprecated unit format

|

|

22= Temperature

|

Indicates temperature, measured in degrees Celsius (°C)

|

|

23= Voltage

|

Indicates RMS voltage measured over complete line cycles, expressed in volts (V)

|

|

Reading Time

|

STRING-ASCII

|

This property shall contain the date and time that the reading data was acquired from the sensor

|

|

Reading Range Min

|

INT32

|

The minimum possible value for this sensor

|

|

Reading Range Max

|

INT32

|

The maximum possible value for this sensor

|

|

Accuracy

|

REAL

|

The estimated percent error of measured versus actual values. Deprecated in v1.8 and later.

|

|

Precision

|

REAL

|

The number of significant digits in the reading

|

|

Sensor Reset Time

|

STRING-ASCII

|

The date and time when the time-based properties were last reset

|

|

Reading: Upper Critical Limit

|

REAL

|

A user-defined value at which the reading is considered above normal range but not yet fatal

|

|

Activation: Upper Critical Limit

|

UINT8

|

The value at which the reading is above normal range but not yet fatal

|

|

0= Activation

|

The direction of crossing that activates this threshold

|

|

1= DwellTime

|

The duration the sensor value must violate the threshold before the threshold is activated

|

|

2= HysteresisDuration

|

The duration the sensor value must not violate the threshold before the threshold is deactivated

|

|

3= HysteresisReading

|

The reading offset from the threshold value required to clear the threshold

|

|

4= Reading

|

The threshold value

|

|

Reading: Lower Caution Limit

|

REAL

|

A user-defined value at which the reading is considered below normal range

|

|

Activation: Lower Caution Limit

|

UINT8

|

The value at which the reading is below normal range

|

|

0= Activation

|

The direction of crossing that activates this threshold

|

|

1= DwellTime

|

The duration the sensor value must violate the threshold before the threshold is activated

|

|

2= HysteresisDuration

|

The duration the sensor value must not violate the threshold before the threshold is deactivated

|

|

3= HysteresisReading

|

The reading offset from the threshold value required to clear the threshold

|

|

4= Reading

|

The threshold value

|

|

Reading: Lower Critical Limit

|

REAL

|

A user-defined value at which the reading is considered below normal range but not yet fatal

|

|

Activation: Lower Critical Limit

|

UINT8

|

The value at which the reading is below normal range but not yet fatal

|

|

0= Activation

|

The direction of crossing that activates this threshold

|

|

1= DwellTime

|

The duration the sensor value must violate the threshold before the threshold is activated

|

|

2= HysteresisDuration

|

The duration the sensor value must not violate the threshold before the threshold is deactivated

|

|

3= HysteresisReading

|

The reading offset from the threshold value required to clear the threshold

|

|

4= Reading

|

The threshold value

|

|

Reading: Lower Fatal Limit

|

REAL

|

A user-defined value at which the reading is below normal range and fatal

|

|

Activation: Lower Fatal Limit

|

UINT8

|

The value at which the reading is below normal range and fatal

|

|

0= Activation

|

The direction of crossing that activates this threshold

|

|

1= DwellTime

|

The duration the sensor value must violate the threshold before the threshold is activated

|

|

2= HysteresisDuration

|

The duration the sensor value must not violate the threshold before the threshold is deactivated

|

|

3= HysteresisReading

|

The reading offset from the threshold value required to clear the threshold

|

|

4= Reading

|

The threshold value

|

|

Reading: Upper Caution Limit

|

REAL

|

A user-defined value at which the reading is considered above normal range

|

|

Activation: Upper Caution Limit

|

UINT8

|

The value at which the reading is above normal range

|

|

0= Activation

|

The direction of crossing that activates this threshold

|

|

1= DwellTime

|

The duration the sensor value must violate the threshold before the threshold is activated

|

|

2= HysteresisDuration

|

The duration the sensor value must not violate the threshold before the threshold is deactivated

|

|

3= HysteresisReading

|

The reading offset from the threshold value required to clear the threshold

|

|

4= Reading

|

The threshold value

|

|

Reading: Upper Fatal Limit

|

REAL

|

A user-defined value at which the reading is above normal range and fatal

|

|

Activation: Upper Fatal Limit

|

UINT8

|

The value at which the reading is above normal range and fatal

|

|

0= Activation

|

The direction of crossing that activates this threshold

|

|

1= DwellTime

|

The duration the sensor value must violate the threshold before the threshold is activated

|

|

2= HysteresisDuration

|

The duration the sensor value must not violate the threshold before the threshold is deactivated

|

|

3= HysteresisReading

|

The reading offset from the threshold value required to clear the threshold

|

|

4= Reading

|

The threshold value

|

|

Adjusted Max Allowable Operating Value

|

REAL

|

The adjusted maximum allowable operating value for this equipment based on the environmental conditions

|

|

Adjusted Min Allowable Operating Value

|

REAL

|

The adjusted minimum allowable operating value for this equipment based on the environmental conditions

|

|

Apparent VA

|

REAL

|

The product of voltage and current for an AC circuit, in volt-ampere units

|

|

Apparent kVAh

|

REAL

|

This property shall contain the apparent energy, in kilovolt-amperehour units, for an electrical energy measurement

|

|

Average Reading

|

REAL

|

The average sensor value

|

|

Averaging Interval

|

STRING-ASCII

|

The interval over which the average sensor value is calculated

|

|

Averaging Interval Achieved

|

BIT

|

Indicates that enough readings were collected to calculate the average sensor reading over the averaging interval time

|

|

Calibration

|

REAL

|

This property shall contain the offset applied to the raw sensor value to provide a calibrated value for the sensor as returned by the Reading property. The value of this property shall follow the units of the Reading property for this sensor instance. Updating the value of this property shall not affect the value of the CalibrationTime property

|

|

Calibration Time

|

STRING-ASCII

|

The date and time that the sensor was last calibrated

|

|

Electrical Context

|

UINT8

|

The combination of current-carrying conductors

|

|

0= Line1

|

The circuits that share the L1 current-carrying conductor

|

|

1= Line1ToLine2

|

The circuit formed by L1 and L2 current-carrying conductors

|

|

2= Line1ToNeutral

|

The circuit formed by L1 and neutral current-carrying conductors

|

|

3= Line1ToNeutralAndL1L2

|

The circuit formed by L1, L2, and neutral current-carrying conductors

|

|

4= Line2

|

The circuits that share the L2 current-carrying conductor

|

|

5= Line2ToLine3

|

The circuit formed by L2 and L3 current-carrying conductors

|

|

6= Line2ToNeutral

|

The circuit formed by L2 and neutral current-carrying conductors

|

|

7= Line2ToNeutralAndL1L2

|

The circuit formed by L1, L2, and Neutral current-carrying conductors

|

|

8= Line2ToNeutralAndL2L3

|

The circuits formed by L2, L3, and neutral current-carrying conductors

|

|

9= Line1ToNeutralAndL1L2

|

The circuit formed by L1, L2, and neutral current-carrying conductors

|

|

10= Line3

|

The circuits that share the L3 current-carrying conductor

|

|

11= Line3ToLine1

|

The circuit formed by L3 and L1 current-carrying conductors

|

|

12= Line3ToNeutral

|

The circuit formed by L3 and neutral current-carrying conductors

|

|

13=Line3ToNeutralAndL3L1

|

The circuit formed by L3, L1, and neutral current-carrying conductors

|

|

14=LineToLine

|

The circuit formed by two current-carrying conductors

|

|

15=LineToNeutral

|

The circuit formed by a line and neutral current-carrying conductor

|

|

16=Neutral

|

The grounded current-carrying return circuit of current-carrying conductors

|

|

17=Total

|

The circuit formed by all current-carrying conductors

|

|

Implementation

|

UINT8

|

The implementation of the sensor

|

|

0= PhysicalSensor

|

The reading is acquired from a physical sensor

|

|

1= Reported

|

The reading is obtained from software or a device

|

|

2= Synthesized

|

The reading is obtained by applying a calculation on one or more properties or multiple sensors. The calculation is not provided

|

|

Lowest Reading

|

REAL

|

The lowest sensor value

|

|

Lowest Reading Time

|

STRING-ASCII

|

The time when the lowest sensor value occurred

|

|

Lifetime Reading

|

REAL

|

The total accumulation value for this sensor

|

|

Manufacturer

|

STRING-ASCII

|

The manufacturer of this sensor

|

|

Min Allowable Operating Value

|

REAL

|

The minimum allowable operating value for this equipment

|

|

Max Allowable Operating Value

|

REAL

|

The maximum allowable operating value for this equipment

|

|

Model

|

STRING-ASCII

|

The model number of the sensor

|

|

Part Number

|

STRING-ASCII

|

The part number of the sensor

|

|

Peak Reading

|

REAL

|

The peak sensor value

|

|

Peak Reading Time

|

STRING-ASCII

|

The time when the peak sensor value occurred

|

|

Physical Context

|

UINT8

|

The area or device to which this sensor measurement applies

|

|

0= Accelerator

|

An accelerator

|

|

1= ACInput

|

An AC input

|

|

2= ACMaintenanceBypassInput

|

An AC maintenance bypass input

|

|

3= ACOutput

|

An AC output

|

|

4= ACStaticBypassInput

|

An AC static bypass input

|

|

5= ACUtilityInput

|

An AC utility input

|

|

6= ASIC

|

An ASIC device, such as a networking chip or chipset component

|

|

7= Back

|

The back of the chassis

|

|

8= Backplane

|

A backplane within the chassis

|

|

9= Battery

|

A battery

|

|

10= Board

|

A circuit board

|

|

11= Chassis

|

The entire chassis

|

|

12= ComputeBay

|

Within a compute bay

|

|

13= CoolingSubsystem

|

The entire cooling, or air and liquid, subsystem

|

|

14= CPU

|

A processor (CPU)

|

|

15= CPUSubsystem

|

The entire processor (CPU) subsystem

|

|

16= DCBus

|

A DC bus

|

|

17= Exhaust

|

The air exhaust point or points or region of the chassis

|

|

18= ExpansionBay

|

An expansion bay

|

|

19= ExpansionSubsystem

|

A group of expansion bays

|

|

20= Fan

|

A fan

|

|

21= Filter

|

A filter

|

|

22= FPGA

|

An FPGA

|

|

23= Front

|

The front of the chassis

|

|

24= GPU

|

A graphics processor (GPU)

|

|

25= GPUSubsystem

|

The entire graphics processor (GPU) subsystem

|

|

26= Intake

|

The air intake point or points or region of the chassis

|

|

27= LiquidInlet

|

The liquid inlet point of the chassis

|

|

28= LiquidOutlet

|

The liquid outlet point of the chassis

|

|

29= Lower

|

The lower portion of the chassis

|

|

30= Manager

|

A management controller, such as a BMC (baseboard management controller).

|

|

31= Memory

|

A memory device

|

|

32= MemorySubsystem

|

The entire memory subsystem

|

|

33= Motor

|

A motor

|

|

34= NetworkBay

|

Within a networking bay

|

|

35= NetworkingDevice

|

A networking device

|

|

36= PowerOutlet

|

An electrical outlet

|

|

37= PowerSubsystem

|

The entire power subsystem

|

|

38= PowerSupply

|

A power supply

|

|

39= PowerSupplyBay

|

A power supply bay

|

|

40= Pump

|

A pump

|

|

41= Rectifier

|

A rectifier device

|

|

42= Reservoir

|

A reservoir

|

|

43= Room

|

The room

|

|

44= StorageBay

|

Within a storage bay

|

|

45= StorageDevice

|

A storage device

|

|

46=StorageSubsystem

|

A storage subsystem

|

|

47=Switch

|

A switch device

|

|

48= SystemBoard

|

The system board (PCB)

|

|

49= Transceiver

|

A transceiver

|

|

50= Transformer

|

A transformer

|

|

51= TrustedModule

|

A trusted module

|

|

52= Upper

|

The upper portion of the chassis

|

|

53= VoltageRegulator

|

A voltage regulator device

|

|

Physical Sub Context

|

UINT8

|

The usage or location within a device to which this sensor measurement applies

|

|

0= Input

|

The input

|

|

1= Output

|

The output

|

|

Power Factor

|

REAL

|

The power factor for this sensor

|

|

Reactive VAR

|

REAL

|

This property shall contain the arithmetic mean of product terms of instantaneous voltage and quadrature current measurements calculated over an integer number of line cycles for a circuit

|

|

Reactive kVARh

|

REAL

|

This property shall contain the reactive energy, in kilovolt-amperehours (reactive) units, for an electrical energy measurement

|

|

Reading Accuracy

|

REAL

|

This property shall contain the accuracy of the value of the Reading property for this sensor

|

|

Reading Basis

|

UINT8

|

The basis for the reading of this sensor

|

|

0= Delta

|

A reading that reports the difference between two measurements

|

|

1= Headroom

|

A reading that decreases as it approaches a defined reference point

|

|

2= Zero

|

A zero-based reading

|

|

Sensing Interval

|

STRING-ASCII

|

The time interval between readings of the sensor

|

|

Serial Number

|

STRING-ASCII

|

The serial number of the sensor

|

|

Spare Part Number

|

STRING-ASCII

|

The spare part number of the sensor

|

|

Speed RPM

|

REAL

|

This property shall contain a reading of the rotational speed of the device in revolutions per minute (RPM) units

|

|

THD Percent

|

REAL

|

This property shall contain the total harmonic distortion of the Reading property in percent units, typically 0 to 100

|

|

Location Ordinal Value

|

UINT32

|

The number that represents the location of the sensor

|

|

Location Type

|

UINT8

|

The type of location of the part

|

|

0= Backplane

|

A backplane (v1.12+)

|

|

1= Bay

|

A bay

|

|

2= Connector

|

A connector or port

|

|

3= Embedded

|

Embedded within a part (v1.13+)

|

|

4= Slot

|

A slot

|

|

5= Socket

|

A socket

|

|

Orientation

|

UINT8

|

The orientation for the ordering of the slot enumeration

|

|

0= BackToFront

|

The ordering for the LocationOrdinalValue is back to front

|

|

1= BottomToTop

|

The ordering for LocationOrdinalValue is bottom to top

|

|

2= FrontToBack

|

The ordering for LocationOrdinalValue is front to back

|

|

3= LeftToRight

|

The ordering for the LocationOrdinalValue is left to right

|

|

4= RightToLeft

|

The ordering for the LocationOrdinalValue is right to left

|

|

Reference

|

UINT8

|

The reference point for the part location. Provides guidance about the general location of the part

|

|

0= Bottom

|

The part is in the bottom of the unit

|

|

1= Front

|

The part is in the front of the unit

|

|

2= Left

|

The part is on the left side of the unit

|

|

3= Middle

|

The part is in the middle of the unit

|

|

4= Rear

|

The part is in the rear of the unit

|

|

5= Right

|

The part is on the right side of the unit

|

|

6= Top

|

The part is in the top of the unit

|

|

Service Label

|

STRING-ASCII

|

Used to identify or describe a service

|

|

Location Info

|

STRING-ASCII

|

Used to provide information about a location

|

|

Location Rack

|

STRING-ASCII

|

Identifies the specific rack or slot location within a system or physical environment

|

|

Location Row

|

STRING-ASCII

|

Indicates the row within a physical structure

|

|

Location Offset

|

INT32

|

Represents an offset or positional adjustment within a location

|

|

Rack Offset Units

|

UINT8

|

The type of rack units in use

|

|

0= EIA_310

|

A rack unit that is equal to 1.75 in (44.45 mm)

|

|

1= OpenU

|

A rack unit that is equal to 48 mm (1.89 in)

|

|

Room

|

STRING-ASCII

|

Provides the name or identifier of a room

|

|

Floor

|

STRING-ASCII

|

Specifies the floor or level where a location or item is situated

|

|

Voltage Type

|

UINT8

|

The type of input voltage the sensor monitors

|

|

0= AC

|

Alternating current

|

|

1= DC

|

Direct current

|